Some deliveries may take a little longer than usual due to regional shipping conditions.

Customer Services

Copyright © 2025 Desertcart Holdings Limited

🚀 Print your future today—because your ideas deserve zero downtime!

The Official Creality Ender 3 is a fully open-source, budget-friendly 3D printer with an 8.66x8.66x9.84 inch build volume. It features a resume printing function to protect your projects from power interruptions, an upgraded extruder with quiet V-shape POM wheels for smooth operation, and a fast-heating bed that reaches 100°C in 5 minutes. Ideal for beginners and DIY enthusiasts, it requires about 2 hours to assemble and supports printing via SD card or PC connection. This printer combines affordability with reliable performance, making it a top choice for entry-level 3D printing and hands-on learning.

| ASIN | B07BR3F9N6 |

| Best Sellers Rank | #20,274 in Industrial & Scientific ( See Top 100 in Industrial & Scientific ) #45 in 3D Printers |

| Customer Reviews | 4.1 4.1 out of 5 stars (16,221) |

| Date First Available | March 27, 2018 |

| Is Discontinued By Manufacturer | No |

| Item Weight | 15.43 pounds |

| Item model number | Ender 3 |

| Manufacturer | Creality 3D |

| Product Dimensions | 16.14 x 16.54 x 18.31 inches |

L**Z

Amazing printer!

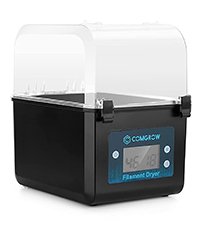

The Ender 3 marked my entry into the 3D-printing world, and I love it! The 3D printer has been a godsend! If you're also newbie and searching for advice, here's my brief take on the Ender 3. It's awesome! The Ender 3 arrives in pieces that you must assemble. Since it is essentially a robot, assembly can seem overwhelming at first, but if you take it one step at a time, you'll be printing in no time. I found the printed instructions accompanying the unit to be more sizzle than steak, but, fortunately there are several videos on YouTube that make assembly a breeze. Believe it or not, assembling the unit yourself is beneficial because it familiarizes you with the device. It will allow you to easily make the minor adjustments that 3D printers often require. My wife and I have found that 3D printing comes with somewhat of a steep learning curve, but it's fun. YouTube and websites such as "all3DP dot com" have proven themselves to be life savers. The most common adjustments you'll make while 3D printing is "bed leveling." In truth, though, you're not actually "leveling" the print bed, but rather you're ensuring that the print nozzle is uniformly distanced from the bed (the print surface) on all its 4 corners. The nozzle needs to be super close, too. ...not about an inch or two away from the print bed, but rather it needs to be no further than the thickness of a piece of paper. Crazy, huh? When my wife and I printed a test file provided by Creality (the manufacturer), we frankly sat mesmerized at the unit's precision. It was like staring into a campfire and getting lost in the flames. The nozzle just zipped back and forth across the print bed leaving tiny bits of corn-based "plastic" one layer at a time, and eventually (over time) created a cat/dog thingy. In search of more things to print, we settled on two websites with tons of 3D-printable files that are very often free to download. The websites are "thingiverse dot com" and "cults3d dot com". The latter site takes longer to load, but seems to have more options. Creality has one too, but I haven't really checked it out yet. It's important to note that the files you download from such websites are *.stl files, whereas the Ender 3 needs *.gcode files. To make the file conversion, we downloaded a piece of software called Cura. It appears to be the best (free) software on the market for "slicing" 3D files into *.gcode files. That too has a steep learning curve, complete with complicated settings. But fortunately there are lots of tutorials online along with settings you can copy from experts. I mostly rely on "all3DP dot com" for that. After a while, we decided to invent our own designs and then print them into existence. In my opinion, the cat's meow -- the best and easiest 3D design application -- is Fusion360. It has a limited free version for students and schools, but otherwise it's quite pricey. My wife then found free, open-sourced design software called FreeCAD. We love it, and haven't turned back since. The filament we prefer is PLA. In our experience, PLA produces little to no fumes and it's guilt-free because it's corn-based and biodegradable. It should be noted, though, that not all PLA is created equally. This is primarily because (according to what I've read) pigments affect the PLA in different ways. So, when I order PLA from Amazon, I always look for the PLA with the most and highest reviews. Then, I refer upon their temperature recommendations. Overall, we absolutely love the Ender 3. At under $200, it's extremely affordable, and the process of printing things into existence can be (in my experience) somehow transformative. And if you find yourself confused about something, take my advice by not wasting time by trying to figure it out for yourself. Just refer to the experts on any of the websites I mentioned so, later on, you can focus on things that really matter...like design. Note: the bearing on a little fan went out. So, I reached out to Comgrow, they got back to me immediately, and now a new fan is on the way. No fuss no muss. Finally, at the risk of getting to personal, I'm a disabled veteran who benefits from focusing on tangible things. The process of 3D printing has proven itself to be such a godsend in that regard, that I think the VA should seriously explore ways of getting more vets 3D printing. I hope this helped newbies like me. Happy printing!

D**R

Works well and easy printing

I've only printed a few things so far but it's enough to give some good feedback. At this price point don't expect any frills. That said this bare bones printer performs great. First off from my pictures you'll notice I upgraded the print bed to glass. It's only an extra $12 at the time I purchased. I read some other info online that lead me to believe this would be more likely to be level and perform better. i don't regret it. It works great. My advice would be to take your time assembling this printer. Expect it to take about 4 hours, perhaps more. Make sure everything is tight and aligned properly in terms of the rollers, belts etc. Do not rely on the quick start guide or included instructions. Go out to Youtube and follow the assembly video. Pause it for each step. When you are done stay on Youtube. There is a "Complete beginner's guide" on there from an Australian creator that demonstrates using this exact model. I noticed his menus are a little different due to software changes but his leveling guide and calibration files work great. For being one of the cheapest printers you can get the performance is surprising. I'm very happy with the print quality. I love that I can use tools on Linux or Windows. You don't need to be plugged in as you can simply print from G code on the included micro SD card. The videos online can get you up and running quickly. Every tool needed to build and run the printer are in the box. Nice touch. There is a small amount of PLA material but you will want to order more right away. The included spool is small and really only enough for a couple test prints. If you are a beginner why spend more? This is the perfect first printer. Update: I thought I would add to my review now that I have had some time working with this printer. I've made a lot of improvements to the device I first received. The nice thing is most of the improvements are cheap or you can print them. First thing to note: I was having a lot of problems with printing anything large that took a bit of time. After a lot of digging I found the hotend shipped with the printer was (in my opinion) put together wrong. They either built it cold or inserted the nozzle before the heat break. Either way there was a gap that could not be fixed in the hotend. I bought a Creality spider hotend which is all metal. Way better and it works great. Add to that a BL Touch sensor for autoleveling the bed. Best addition ever. You still need to start with a level bed but it fixes all the little problems with uneven bed surfaces and stopped my extruder problems. While on the extruder. Calibrate your machine! Take the time to measure the output from your extruder. They use a generic setting from the factory. You NEED to set up this machine. Calibrate the extruder, the retraction distance, the nozzle temp for the filiment etc. Pay attention to the details and you will get great results. Really happy with this printer. It takes work but it's a fun project that leads to other projects, and for a beginner it's hard to beat. Some say you should buy higher end and avoid all the minor issues. I disagree. I think this has been a learning experience that prompted me to understand the machine. I think that basic knowledge of the process is important. Your mileage may vary.

P**C

I really gotta give props to Creality for making this printer so affordable and (relatively) easy to set up and use. Since getting it I learned a <ton> of stuff about 3D printing (both by being forced to do it and trying to troubleshoot all the different issues :P) It's a great printer for the price, not sure what else I can say. Initial assembly was relatively easy and took around an hour. Then I realised I haven't done it properly so I had to re-assemble parts I assembled before (another 1h). Then a couple of days later I realised the frame is not straight... So I disassembled and re-levelled the whole thing from scratch (another 2h or so) Then i've done it yet again a couple of days later to straighten the gantry :P Unfortunately factory pre-assembled parts were not perfectly assembled. The bed is not perfectly even either, seems a bit warped but oh well the glass bed upgrade is too expensive. Usage is straightforward after assembly, there's an amazing amount of 3D-printable improvements to the Ender 3, tons of guides and information readily available. SD card slot is a great addition but you'll probably want to move to an Octoprint setup for ease of use and to flash a more recent Marlin firmware. Unfortunately the Pause feature has bugged out multiple times on me on the original firmware (just freezes printer in place, ruining prints) but at least the power-loss recovery works fine (once it freezes just shut it off and back on and it will give you an option to resume). No such issues with the custom-built Marlin fw. Worth noting is that my unit came with a 4.2.2 32-bit motherboard, an extruder guide enforced with metal and adjustable tension. Attached amount of filament was almost enough to print the sample doggy figure - you can clearly see where the filament ran out ;( Overall it's a fun learning experience but if you're expecting to just "buy, print and forget" - this might be the best choice for you as it has no auto bed levelling and other features present in more expensive printers (unless you upgrade it yourself) Definitely watch one or two assembly videos to get an idea of what to look out for during assembly, it will save you time in the longer run

O**R

L'imprimante qui m'a été livrée avait un défaut de taille : son plateau chauffant ne pouvait pas être mis à niveau : il y avait toujours quoi que l'on fasse, et même en plaçant une plaque de verre de 4mm sur le plateau, un coin qui restait désespérément plus bas, de plusieurs mm, que les 3 autres coins. Avec 2 molettes de réglage (sur les 4 présentes sous le plateau) qui finissaient par sortir de leur vis en fin de procédure de réglage. Imaginez donc un plateau de travers, qui finit par ne tenir que sur 2 vis… C’est là-dessus que je me suis efforcé d’imprimer pendant plusieurs mois. Du coup, impossible d'imprimer sur plus d'un quart de la surface du plateau, parfois un tiers avec un peu de chance, pour des modèles de pas plus de 2 cm d'épaisseur. J'ai passé de longs mois à essayer de régler ce souci, avec l'aide de nombreuses personnes expérimentées, vérifié toutes les pièces une à une, tout démonté, tout remonté, tout calibré, acheté des pièces détachées pour essayer de régler le problème en remplaçant ou complétant certaines pièces : rien à faire. Problème d'autant plus gênant qu'il n'était visiblement pas très commenté sur le Net. En désespoir de cause, j'ai fait appel au vendeur. Après plusieurs semaines d'échanges par mail, malgré le fait qu'il m'ait demandé mail après mail de grosso modo tout démonter pièce par pièce (et bien sûr de photographier voire filmer chaque étape pour lui envoyer), et quelques demandes pour le moins hasardeuses, parfois sans lien apparent avec le problème, voire contradictoires (un coup le problème viendrait du fait que telle pièce est trop haute, plus tard le problème viendrait du fait qu'elle est trop basse. Plus tard encore cela viendrait d'une autre pièce. etc...), il a fini par en déduire que le problème viendrait d'une pièce qui n'avait visiblement aucun soucis apparent. Et me l'a remplacé, ce qui a, à ma grande surprise, résolu le soucis rencontré, alors même que personne n'avait pu identifier ni même envisager que le problème pourrait venir de là (barre de l'axe des Y à peine, mais alors à peine voilée). Il m'a également remplacé sans soucis un moteur qui avait lâché. Si j'ai été un peu refroidi par cette première expérience en impression 3D sur un imprimante défectueuse, j'ai été agréablement surpris par la qualité du SAV. Chose assez rare pour être signalé et qui justifie amplement mon appréciation à 5 étoiles en complément de la qualité de l'imprimante elle-même. Ce vendeur a une très bonne communication, répond assez rapidement, est réactif quand il s'agit d'envoyer une pièce de rechange lorsque nécessaire (qui met toutefois un peu de temps à arriver mais bon, cela reste ici normal). S'agissant de l'imprimante, c'est une imprimante : - de grande qualité, - moyennement bruyante, - facile à calibrer (dès lors qu'elle n'a pas de soucis de conception d'usine comme celui que j'ai rencontré), - assez compacte avec malgré tout une surface d'impression très appréciable, - qui rend des impressions très précises, - qui imprime sans soucis du PLA, du PETG, du flexible, du bois, ... - son plateau chauffant chauffe rapidement. Si votre imprimante souffre d'un plateau chauffant légèrement en creux en son centre, l'installation d'une plaque de verre Creality (vendue séparément) sur le plateau chauffant résouds ce soucis, et offre un gain d'adhésion et de facilité à décoller les impressions. En conclusion, de toutes les imprimantes du marché à ce jour dans cette gamme de prix, c'est celle que je rachèterai sans hésiter une seconde si la mienne devait me lâcher complètement. D'autres offrent des "gadgets" en plus (détecteur de fin de filament, BLtouch, etc...), mais ont visiblement en contre-partie une moins bonne qualité d'impression. Je préfère pour ma part si nécessaire avoir une imprimante qui imprime le mieux possible de base, quitte à acheter séparément ces compléments ultérieurement. (Si mon commentaire vous a aidé, n'hésitez pas à le dire en cliquant sur le bouton "UTILE" ci-dessous)

F**O

A Ender 3 Pro é uma impressora surpreendente capaz de fazer impressões em alto detalhe de uma maneira incrível, entretanto impressão 3D segue sendo algo um tanto complexo. A montagem é rapida e leva em torno de uma hora, o cartão micro sd incluído vem com um vídeo mostrando como montar e com um manual bem completo, porém em inglês. Incluí também alguns exemplos e um software de slicing. O que mais agrada na Ender 3 Pro é sua comunidade ativa, com muitas opções de ajustes, upgrades e ajudas online, o que facilitou muito iniciar as impressões. Estou feliz com a compra, e achei o preço aceitável para o Brasil. O envio foi rápido e a entrega também.

A**N

The box arrived pre-dented inside another amazon box, meaning it was dented before placed inside, luckily due to insane overengineering of the packaging everything was in perfect order inside the box. Took 1/2 an hour to confirm all the parts were there, then another 1.5 hours to assemble, there were some discrepancies between the manual and the online video, but nothing major. I assembled purely by sight and everything came together perfectly level. Leveling manually is a bit annoying and lead to a couple of failed prints, but once I got the hang of it things started coming out great. I've had some issues with more advanced items like interrupting the print to add in a magnet causing weak points and the prints would fail about 1cm up from the magnet, pretty sure I can work that out by tweaking the temperature and perhaps shifting the resume layers down a fraction of a millimeter to improve bonding though. The base print speed is rather slow, 50mm/s but I intentionally purchased the base model with the plan to upgrade the main components piece by piece after the next couple of months for the learning experience. My one complaint is that the stock build plate that comes with it tends to stick to the prints like superglue, good for larger bulky prints, but terrible for thinner prints that fall apart when scrapped. So I replaced it earlier than originally planned with a PEI sheet which releases the print as the plate cools. Creality emailed me the day before it arrived, preemptively offering support with setup and use, I never ended up needing it, but it's nice to know it's there if I did. Overall super happy with the purchase, can't wait to supercharge this puppy. Overall, super happy with the purchase.

S**M

La stampante è arrivata nei tempi previsti con un adeguato imballaggio. Si configura come stampante Kit ma in realtà richiede l'assemblaggio solo delle parti principali come montanti verticali, alimentatore, asse X, motore asse Z e alcuni cablaggi. Assieme alla stampante vengono forniti tutti gli utensili per il montaggio oltre ad una indispensabile spatola affilata e un piccolo tronchese per i filamenti. Fornita anche una micro SD da 8Gb con adattatore USB. L'assemblaggio richiede circa un ora, le istruzioni sono abbastanza chiare ma alcuni video su youtube approfondiscono sicuramente meglio alcuni aspetti al quale fare particolarmente attenzione come la verifica dei corretti allineamenti e la regolazione della giusto attrito tra ruote e guide. Le parti pre-assemblate come la base e il gruppo estrusore meritano comunque una controllata, nel mio caso la base non era perfettamente complanare e pertanto ho dovuto allentare le viti, allineare meglio le barre di alluminio e riassemblare il tutto. Una volta montata la stampante e allineato il piatto è praticamente pronta per stampare anche per un principiante. Il volume di stampa è 220 x 220 x 250 cm anche se il fine corsa degli assi X e Y raggiunge in realtà i 235mm Il piatto riscaldato ha un ottima aderenza, Si riscalda velocemente (le temperature testate personalmente per il PLA tra i 50° e 60°) L'alimentatore ha un fondello chiuso con connettore per il cavo di alimentazione che evita quindi di lasciare esposti i cavi come su alcune stampanti Kit, è presente anche il tasto di accensione e spegnimento. Lo schermo è in una posizione molto comoda per lettura e utilizzo dei comandi, peccato che il circuiti sul retro siano scoperti ed è ovviamente consigliato stampare un carter per chiuderlo. il gruppo estrusore svolge il suo lavoro ma prevedo di sostituire le parti in plastica con delle nuove in alluminio così come un nuovo tubo PTFE La qualità delle stampe è comunque ottima anche senza aver ancora effettuato sostituzioni grazie sopratutto alla struttura decisamente solida. PRO: Rapporto prezzo volume di stampa Struttura molto solida Alimentatore con cablaggio chiuso Facilità di montaggio (in rapporto ad altre stampanti KIT) Qualità di stampa CONTRO: Gruppo estrusore in plastica Retro dello schermo senza protezione. inserimento micro SD abbastanza scomodo In definitiva è una stampante consigliata sopratutto per il prezzo al quale viene proposta attorno ai 190/200 euro, che per volume di stampa e caratteristiche difficilmente trova rivali, ci sono parti migliorabili sia con la sostituzione sia con la stampa di modifiche. Può essere presa in considerazione anche come prima esperienza nel campo della stampa 3d.

Trustpilot

2 months ago

1 day ago